Can You Put A Dry Clean Only Item In The Dryer

Dry cleaning is any cleaning process for wearable and textiles using a solvent other than water.

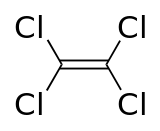

Dry cleaning still involves liquid, but clothes are instead soaked in a water-free liquid solvent, tetrachloroethylene (perchloroethylene), known in the industry every bit "perc", which is the almost widely used solvent. Alternative solvents are 1-bromopropane and petroleum spirits.[i]

Most natural fibers can be washed in h2o but some synthetics (eastward.g., viscose, lyocell, modal, and cupro) react poorly with water and must be dry-cleaned.[two]

History [edit]

Dry cleaning originated[3] with American entrepreneur Thomas L. Jennings. Jennings referred to his method as "dry scouring".

French dye-works operator Jean Baptiste Jolly[4] [a] developed his own method using kerosene and gasoline to clean fabrics.[4] He opened the commencement dry-cleaners in Paris in 1845.[6]

Flammability concerns led William Joseph Stoddard, a dry cleaner from Atlanta, to develop Stoddard solvent (white spirit) as a slightly less combustible culling to gasoline-based solvents. The use of highly combustible petroleum solvents caused many fires and explosions, resulting in government regulation of dry cleaners. After World State of war I, dry cleaners began using chlorinated solvents. These solvents were much less flammable than petroleum solvents and had improved cleaning power.[ citation needed ]

Shift to tetrachloroethylene [edit]

Past the mid-1930s, the dry cleaning industry had adopted tetrachloroethylene (perchloroethylene), or PCE for short, as the solvent. It has excellent cleaning power and is nonflammable and compatible with most garments. Considering it is stable, tetrachloroethylene is readily recycled.[1]

Infrastructure [edit]

Dry cleaning businesses, from the perspective of the customer, are either plants or driblet shops. A establish does on-site cleaning. A drop shop receives garments from customers, sends them to a large plant, and then has the cleaned garment returned to the shop for collection past the customer. The turnaround fourth dimension is longer for a drop shop than for a local plant. However, running a establish requires more work for the concern owner. Since 2022, in some markets, web apps accept been used to schedule low-cost dwelling delivery for dry cleaning.[7]

This cycle minimized the risk of fire or dangerous fumes created past the cleaning process. At this fourth dimension, dry cleaning was carried out in 2 unlike machines—1 for the cleaning process, and the second to remove the solvent from the garments.

Machines of this era were described every bit vented; their drying exhausts were expelled to the atmosphere, the same as many modernistic tumble-dryer exhausts. This not merely contributed to environmental contagion but also much potentially reusable PCE was lost to the temper. Much stricter controls on solvent emissions have ensured that all dry cleaning machines in the Western world are now fully enclosed, and no solvent fumes are vented to the atmosphere.[ citation needed ] In enclosed machines, solvent recovered during the drying procedure is returned condensed and distilled, and so it can be reused to clean further loads or safely disposed of. The majority of modern enclosed machines also incorporate a figurer-controlled drying sensor, which automatically senses when all detectable traces of PCE have been removed. This system ensures that only pocket-sized amounts of PCE fumes are released at the stop of the bicycle.

Mechanism [edit]

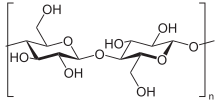

Construction of cellulose, the main constituent of cotton. The many OH groups bind water, leading to swelling of the material and leading to wrinkling, which is minimized when these materials are treated with tetrachloroethylene and other dry cleaning solvents.

In terms of mechanism, dry cleaning selectively solubilizes stains on the commodity. The solvents are non-polar and tend to selectively extract compounds that cause stains. These stains would otherwise only dissolve in aqueous detergents mixtures at high temperatures, potentially damaging delicate fabrics.

Non-polar solvents are likewise proficient for some fabrics, especially natural fabrics, as the solvent does not collaborate with any polar groups inside the textile. Water binds to these polar groups which results in the swelling and stretching of proteins within fibers during laundering. Also, the bounden of water molecules interferes with weak attractions within the fiber, resulting in the loss of the fiber'due south original shape. Later the laundry cycle, water molecules will dry out off. All the same, the original shape of the fibers has already been distorted and this commonly results in shrinkage. Non-polar solvents foreclose this interaction, protecting more delicate fabrics.

The usage of an effective solvent coupled with mechanical friction from tumbling finer removes stains.

Procedure [edit]

A modern dry cleaning machine with touchscreen and SPS command. Manufacturer: EazyClean, type EC124. Photo taken prior to installation.

Serial three dry out cleaning car with PLC control. Manufacturer: BÖWE Textile Cleaning; Frg

A dry out cleaning machine is like to a combination of a domestic washing machine and clothes dryer. Garments are placed in the washing or extraction chamber (referred to as the 'basket' or 'drum'), which constitutes the cadre of the machine. The washing chamber contains a horizontal, perforated drum that rotates within an outer trounce. The shell holds the solvent while the rotating drum holds the garment load. The basket capacity is between near x and forty kg (22 to 88 lb).[ citation needed ]

During the wash bicycle, the chamber is filled approximately one-third full of solvent and begins to rotate, agitating the vesture. The solvent temperature is maintained at 30 degrees Celsius (86 degrees Fahrenheit) or lower, as a higher temperature may damage it. During the launder cycle, the solvent in the sleeping accommodation (ordinarily known every bit the 'cage' or 'tackle box') is passed through a filtration sleeping accommodation so fed back into the 'cage'. This is known as the bike and is connected for the wash elapsing. The solvent is then removed and sent to a distillation unit consisting of a boiler and condenser. The condensed solvent is fed into a separator unit of measurement where any remaining water is separated from the solvent and so fed into the make clean solvent tank. The ideal menses rate is roughly 8 liters of solvent per kilogram of garments per minute, depending on the size of the machine.

Garments are too checked for foreign objects. Items such as plastic pens may dissolve in the solvent bathroom, damaging the textiles. Some cloth dyes are "loose" and will shed dye during solvent immersion. Fragile items, such every bit feather bedspreads or tasseled rugs or hangings, may be enclosed in a loose mesh bag. The density of perchloroethylene is around i.vii g/cm3 at room temperature (70% heavier than h2o), and the sheer weight of captivated solvent may cause the textile to neglect under normal force during the extraction cycle unless the mesh bag provides mechanical support.

Not all stains tin be removed past dry out cleaning. Some need to exist treated with spotting solvents — sometimes by steam jet or by soaking in special stain-remover liquids — before garments are washed or dry cleaned. Likewise, garments stored in soiled condition for a long time are difficult to bring back to their original color and texture.

A typical wash bicycle lasts for 8–15 minutes depending on the type of garments and degree of soiling. During the offset iii minutes, solvent-soluble soils dissolve into the perchloroethylene and loose, insoluble soil comes off. Information technology takes ten–12 minutes after the loose soil has come off to remove the basis-in insoluble soil from garments. Machines using hydrocarbon solvents require a wash cycle of at least 25 minutes because of the much slower charge per unit of solvation of solvent-soluble soils. A dry cleaning surfactant "soap" may also be added.

At the finish of the wash cycle, the auto starts a rinse bicycle where the garment load is rinsed with freshly distilled solvent dispensed from the solvent tank. This pure solvent rinse prevents discoloration acquired by soil particles beingness absorbed back onto the garment surface from the 'dingy' working solvent.

Subsequently the rinse bike, the machine begins the extraction procedure, which recovers the solvent for reuse. Modern machines recover approximately 99.99% of the solvent employed. The extraction cycle begins by draining the solvent from the washing sleeping accommodation and accelerating the basket to 350–450 rpm, causing much of the solvent to spin gratuitous of the fabric. Until this time, the cleaning is washed in normal temperature, as the solvent is never heated in dry cleaning process. When no more solvent can be spun out, the auto starts the drying cycle.

During the drying cycle, the garments are tumbled in a stream of warm air (60–63 °C/140–145 °F) that circulates through the handbasket, evaporating traces of solvent left after the spin cycle. The air temperature is controlled to forestall heat impairment to the garments. The exhausted warm air from the auto and then passes through a chiller unit where solvent vapors are condensed and returned to the distilled solvent tank. Modern dry cleaning machines use a closed-loop organization in which the chilled air is reheated and recirculated. This results in high solvent recovery rates and reduced air pollution. In the early days of dry cleaning, big amounts of perchloroethylene were vented to the temper considering it was regarded as cheap and believed to exist harmless.

Many dry cleaners place cleaned wearing apparel inside sparse clear plastic garment numberless

After the drying bicycle is consummate, a deodorizing (aeration) wheel cools the garments and removes further traces of solvent by circulating cool outside air over the garments and and so through a vapor recovery filter fabricated from activated carbon and polymer resins. After the aeration cycle, the garments are clean and fix for pressing and finishing.

Solvent processing [edit]

A Firbimatic Saver Series. This machine uses activated clay filtration instead of distillation. Information technology uses much less energy than conventional methods.

Working solvent from the washing sleeping accommodation passes through several filtration steps before it is returned to the washing sleeping room. The first step is a button trap, which prevents small objects such as lint, fasteners, buttons, and coins from entering the solvent pump.

Over time, a thin layer of filter block (called "muck") accumulates on the lint filter. The muck is removed regularly (commonly in one case per day) and then processed to recover solvent trapped in the muck. Many machines use "spin disk filters", which remove the muck from the filter by centrifugal forcefulness while it is back done with solvent.

After the lint filter, the solvent passes through an absorptive cartridge filter. This filter, which contains activated clays and charcoal, removes fine insoluble soil and non-volatile residues, forth with dyes from the solvent. Finally, the solvent passes through a polishing filter, which removes any soil not previously removed. The clean solvent is then returned to the working solvent tank. Cooked powder residue is the proper name for the waste material textile generated by cooking downward or distilling muck. It will contain solvent, powdered filter material (diatomite), carbon, non-volatile residues, lint, dyes, grease, soils, and water. The waste sludge or solid remainder from the still contains solvent, water, soils, carbon, and other non-volatile residues. Used filters are some other form of waste every bit is waste water.

To enhance cleaning ability, small amounts of detergent (0.five–1.5%) are added to the working solvent and are essential to its functionality. These detergents emulsify hydrophobic soils and keep soil from redepositing on garments. Depending on the machine's design, either an anionic or a cationic detergent is used.

Symbols [edit]

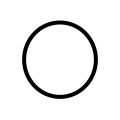

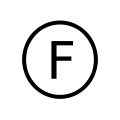

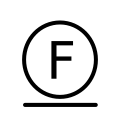

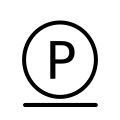

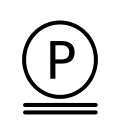

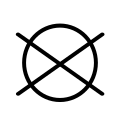

The international GINETEX laundry symbol for dry cleaning is a circle. It may take the letter P inside it to point perchloroethylene solvent, or the letter F to bespeak a flammable solvent (Feuergefährliches Schwerbenzin). A bar underneath the circle indicates that only mild cleaning processes is recommended. A crossed-out empty circle indicates that an item should not be dry cleaned.[8]

-

Professional cleaning symbol

-

Dry out clean, hydrocarbon solvent only (HCS)

-

Gentle cleaning with hydrocarbon solvents

-

Very gentle cleaning with hydrocarbon solvents

-

Gentle cleaning with PCE

-

Very gentle cleaning with PCE

-

Do not dry clean

Solvents used [edit]

Perchloroethylene [edit]

Perchloroethylene (PCE, or tetrachloroethylene) has been in use since the 1930s. PCE is the most common solvent, the "standard" for cleaning performance. It is a highly effective cleaning solvent. Information technology is thermally stable, recyclable, and has depression toxicity. It tin can, however, cause color haemorrhage/loss, especially at higher temperatures. In some cases information technology may damage special trims, buttons, and chaplet on some garments. It is better for oil-based stains (which account for almost 10% of stains) than more than common water-soluble stains (java, wine, blood, etc.). The toxicity of tetrachloroethylene "is moderate to low" and "Reports of human injury are uncommon despite its wide usage in dry cleaning and degreasing".[nine]

Hydrocarbons [edit]

Hydrocarbons are represented by products such as Exxon-Mobil'due south DF-2000 or Chevron Phillips' EcoSolv, and Pure Dry. These petroleum-based solvents are less aggressive only also less constructive than PCE. Although combustible, chance of burn down or explosion can be minimized when used properly. Hydrocarbons are however pollutants. Hydrocarbons retain nigh 10-12% of the market.

A modern dry cleaning machine for use with various solvents

Trichloroethylene [edit]

Trichloroethylene is more than aggressive than PCE but is very rarely used. With superior degreasing properties, it was often used for industrial workwear/overalls cleaning in the past. TCE is classified every bit carcinogenic to humans past the The states Environmental Protection Agency.[10]

Supercritical COtwo [edit]

Supercritical CO2 is an alternative to PCE; however, it is inferior in removing some forms of grime.[11] Additive surfactants improve the efficacy of CO2. [12] Carbon dioxide is almost entirely nontoxic. The greenhouse gas potential is also lower than that of many organic solvents.

The dry cleaning process involves charging a sealed chamber which is loaded with clothes using gaseous carbon dioxide from a storage vessel to approximately 200 to 300 psi. This step in the process is initiated equally a precaution to avoid thermal shock to the cleaning sleeping room. Liquid carbon dioxide is and so pumped into the cleaning chamber from a carve up storage vessel past a hydraulic, or electrically driven pump (which preferably has dual pistons). The pump increases the pressure level of the liquid carbon dioxide to approximately 900 to 1500 psi. A carve up sub-libation reduces the temperature of the carbon dioxide past 2 to 3 degrees Celsius beneath the boiling point in an effort to preclude cavitation which could lead to premature degradation of the pump. [13]

Consumer Reports rated supercritical COtwo superior to conventional methods, just the Drycleaning and Laundry Found commented on its "fairly depression cleaning power" in a 2007 report.[14] Supercritical COtwo is, overall, a mild solvent which lowers its ability to aggressively attack stains.

One deficiency with supercritical CO2 is that its electrical conductivity is low. Every bit mentioned in the Mechanisms section, dry out cleaning utilizes both chemic and mechanical backdrop to remove stains. When solvent interacts with the fabric's surface, the friction dislocates clay. At the same time, the friction likewise builds upwardly an electrical accuse. Fabrics are very poor conductors and then usually, this build-up is discharged through the solvent. This belch does non occur in liquid carbon dioxide and the build-upwardly of an electrical accuse on the surface of the fabric attracts the clay back on to the surface, which diminishes its cleaning efficiency. To compensate for the poor solubility and conductivity of supercritical carbon dioxide, research has focused on additives. For increased solubility, 2-propanol has shown increased cleaning effects for liquid carbon dioxide equally it increases the ability of the solvent to dissolve polar compounds.[fifteen]

Machinery for use of supercritical CO2 is expensive—upward to $xc,000 more than a PCE machine, making affordability difficult for small businesses. Some cleaners with these machines go on traditional machines on-site for more than heavily soiled textiles, but others notice plant enzymes to exist as constructive and more environmentally sustainable.

Other solvents: niche, emerging, etc. [edit]

For decades, efforts have been made to supercede PCE. These alternatives have not proven economical thus far:

- Stoddard solvent – combustible and explosive, 100 °F/38 °C flash point.

- Cfc-113 (Freon-113), a CFC. Now banned equally ozone-unfriendly.

- Decamethylcyclopentasiloxane ("liquid silicone"), chosen D5 for short. It was popularized past GreenEarth Cleaning.[16] It is more than expensive than PCE. It degrades inside days in the surround.

- Dibutoxymethane (SolvonK4) is a bipolar solvent that removes water-based stains and oil-based stains.[17]

- Brominated solvents (n-propyl bromide, Fabrisolv, DrySolv) are solvents with higher KB-values than PCE. This allows faster cleaning, but can damage some synthetic beads and sequins if not used correctly. Healthwise, there are reported risks associated with nPB such as numbness of nerves.[eighteen] The exposure to the solvents in a typical dry cleaner is considered far below the levels required to cause any run a risk.[19] Environmentally, it is approved by the U.S. EPA. It is among the more expensive solvents, just it is faster cleaning, lower temperatures, and quick dry out times.

See besides [edit]

- Fabric restoration

- Listing of laundry topics

- Wet cleaning

Notes [edit]

- ^ In some sources incorrectly[5] referred to as "Jolly-Belin"

References [edit]

- ^ a b David C. Tirsell "Dry Cleaning" in Ullmann'southward Encyclopedia of Industrial Chemistry, Wiley-VCH, Weinheim, 2000. doi:10.1002/14356007.a09_049

- ^ Hunter, Jennifer (22 May 2022). "Dry Cleaning Your Wool Sweaters? Don't Carp". The New York Times . Retrieved 30 May 2022.

- ^ Johnson, Shontavia. "America's always had black inventors – fifty-fifty when the patent system explicitly excluded them". The Chat . Retrieved 2021-06-nineteen .

- ^ a b Oladele Ogunseitan (3 May 2022). Light-green Wellness: An A-to-Z Guide. SAGE Publications. pp. 135–. ISBN978-one-4522-6621-3.

- ^ Ancliffe Prince (1965). Laundering and Cleaning: Yesterday, To-day, and To-morrow. Iliffe Technical Publications.

In Britain America the discovery was for long attributed to a supposed Paris tailor past name of Jolly-Belin [...] Actually the discoverer of drycleaning was non named Jolly-Belin merely Jean-Baptiste Jell

- ^ Reed Business Information (thirteen February 1986). New Scientist. Reed Business Data. pp. 33–. ISSN 0262-4079.

- ^ Lee, Sunny (ane October 2022). "The uncertain time to come of your neighborhood dry cleaner". The Outline . Retrieved 2019-10-11 .

- ^ "Professional textile intendance symbols". GINETEX - Swiss Association for Textile Labelling. Archived from the original on 2022-05-28. Retrieved 2013-07-18 .

- ^ E.-L. Dreher; T. R. Torkelson; K. K. Beutel (2011). "Chlorethanes and Chloroethylenes". Ullmann'southward Encyclopedia of Industrial Chemistry. Weinheim: Wiley-VCH. doi:x.1002/14356007.o06_o01. ISBN978-3527306732.

- ^ EPA Releases Concluding Health Assessment for TCE [1] September 2022. Accessed 2022-09-28.

- ^ "Dry-cleaning with CO2 wins honour [Scientific discipline] Resource". Resource.wur.nl. 2022-ten-12. Archived from the original on 2022-03-12. Retrieved 2013-03-xiv .

- ^ "How tin we utilise carbon dioxide equally a solvent?". Contemporary topics in school science. Retrieved 2016-08-29 .

- ^ "Liquid/supercritical carbon dioxide/dry cleaning system". 1993-12-06. Retrieved 2021-01-02 .

- ^ Drycleaning and Laundry Institute. "The DLI White Paper: Cardinal Data on Industry Solvents." The Western Cleaner & Launderer, August 2007.

- ^ US 5784905, Townsend, Carl W.; Chao, Sidney C. & Purer, Edna M., "Liquid carbon dioxide cleaning system employing a static dissipating fluid", published 1998-07-28

- ^ Tarantola, Andrew. "There'due south a Better Way to Dry Clean Your Clothes". Gizmodo . Retrieved 2016-08-29 .

- ^ Ceballos, Diana Chiliad.; Whittaker, Stephen G.; Lee, Eun Gyung; Roberts, Jennifer; Streicher, Robert; Nourian, Fariba; Gong, Wei; Broadwater, Kendra (2016). "Occupational exposures to new dry cleaning solvents: Loftier-flashpoint hydrocarbons and butylal". Journal of Occupational and Ecology Hygiene. 13 (10): 759–769. doi:10.1080/15459624.2016.1177648. PMC5511734. PMID 27105306.

{{cite journal}}: CS1 maint: uses authors parameter (link) - ^ "HAZARD EVALUATION 1-Bromopropane" Archived 2022-eleven-06 at the Wayback Motorcar July 2003. Accessed 2022-Jan-22

- ^ Azimi Pirsaraei, S. R.; Khavanin, A; Asilian, H; Soleimanian, A (2009). "Occupational exposure to perchloroethylene in dry-cleaning shops in Tehran, Iran". Industrial Health. 47 (2): 155–9. doi:x.2486/indhealth.47.155. PMID 19367044.

External links [edit]

- Hazard Summary provided by the U.s. Environmental Protection Agency.

- NIOSH Safety and Health Topic: Drycleaning

Source: https://en.wikipedia.org/wiki/Dry_cleaning

Posted by: hubbardtheigners.blogspot.com

0 Response to "Can You Put A Dry Clean Only Item In The Dryer"

Post a Comment